42 CMRO4

DESCRIZIONE

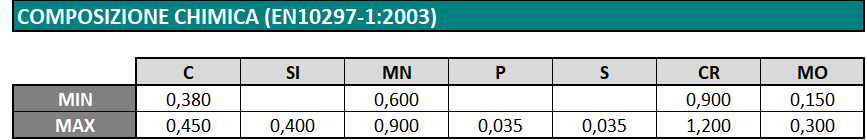

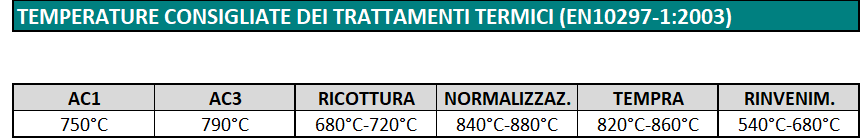

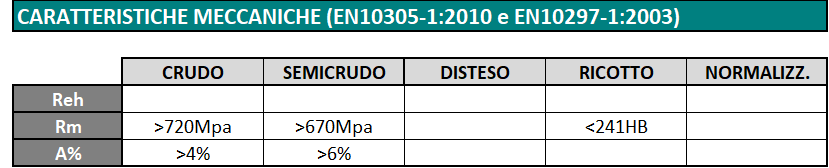

It is a quenched and tempered alloy steel that represents excellence in its class, thanks to the optimal combination of carbon, chromium, and molybdenum. The presence of these elements gives the steel exceptional hardenability, making it particularly suitable for quenching and tempering processes.

The remarkable wear resistance of 42CrMo4 makes it suitable for various applications, while its suitability for nitriding treatment positions it as an advantageous choice to further enhance its surface properties.

In summary, 42CrMo4 steel is characterized by a unique combination of properties, including excellent hardenability, high wear resistance, and suitability for nitriding treatment, making it a prominent choice for mechanical applications that require superior performance.

IMPIEGHI

In general, it finds widespread use in the construction of mechanical components subjected to static and dynamic loads.

In the motorcycle, automotive industry, and other engineering applications, this type of steel is chosen to ensure the necessary robustness for components that must withstand variable and prolonged stresses over time.